Comparing Stainless Steel Wire Mesh with Other Mesh Materials

Stainless steel wire mesh is a common choice, but there are other different types of mesh materials available as well. This article compares the characteristics and advantages of stainless steel wire mesh with other mesh materials, aiming to help readers make informed decisions when choosing the most suitable mesh for their specific needs.

Introduction:

Mesh materials are essential components used in industries ranging from manufacturing and construction to healthcare and environmental sectors. Each mesh material possesses distinct properties that make it suitable for particular applications. Among them, stainless steel wire mesh has gained widespread popularity due to its outstanding features. However, it's essential to explore and understand how it compares to other available mesh materials in terms of performance and functionality.

Stainless Steel Wire Mesh:

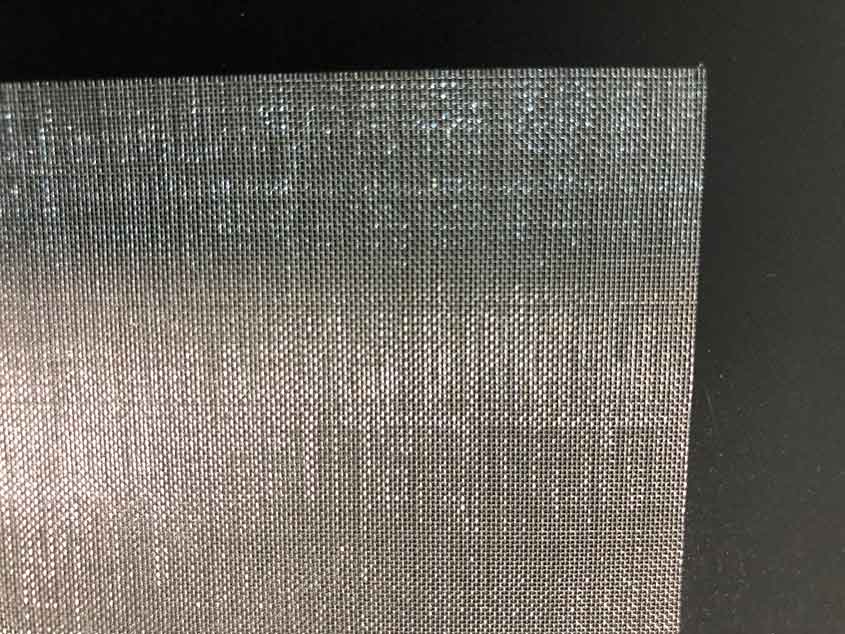

Corrosion Resistance: One of the primary advantages of stainless steel wire mesh is its excellent resistance to corrosion and rust, making it suitable for applications in harsh and corrosive environments.

Strength and Durability: Stainless steel wire mesh is known for its high strength and durability, ensuring it can withstand mechanical stresses and maintain integrity over extended periods.

Fine Filtration Capability: The fine mesh structure allows stainless steel wire mesh to effectively filter out tiny particles, making it ideal for precision applications such as pharmaceutical and food processing.

Brass Wire Mesh:

Conductivity: Brass wire mesh offers good electrical conductivity, making it suitable for applications where electrical current flow is necessary, such as in electronics and electrical components.

Aesthetic Appeal: Brass exhibits an attractive golden appearance, making brass wire mesh a preferred choice for decorative applications, architectural projects, and interior design.

Moderate Corrosion Resistance: While brass has reasonable corrosion resistance, it may not be as robust as stainless steel in highly corrosive environments.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China